CuSn5-5-5 cast copper alloy, as a high-quality material that combines high strength, excellent wear resistance, excellent casting performance and excellent corrosion resistance, has occupied an important position in many industrial fields since its launch. According to industry data, due to its unique properties, the market share of CuSn5-5-5 alloy in high-end machinery manufacturing, marine engineering and other fields has been increasing year by year. This article will deeply explore the composition, performance characteristics, application fields, processing technology and future development trends of CuSn5-5-5 cast copper alloy, aiming to provide a more comprehensive and in-depth understanding for practitioners in related industries.

1. Composition of CuSn5-5-5 cast copper alloy

CuSn5-5-5, its name intuitively reveals its main components: copper (Cu) accounts for about 90%, tin (Sn) content is about 5% (the fluctuation range in actual production is 4.5%-5.5%), and trace alloying elements such as zinc (Zn) and phosphorus (P), the total amount does not exceed 5%. This precise alloy ratio gives CuSn5-5-5 alloy unique physical and chemical properties, making it stand out among many materials and become the first choice for many industrial applications.

2. Performance characteristics

High strength and wear resistance

The tensile strength of CuSn5-5-5 alloy can reach about 350MPa, and the hardness is as high as HB100, which enables it to withstand extremely high mechanical stress without deformation or fracture. At the same time, its wear resistance is excellent. Even in extreme friction environments, the alloy surface can remain smooth for a long time, significantly reducing maintenance costs and replacement frequency. This feature makes CuSn5-5-5 alloy an ideal material for manufacturing high-precision and high-load mechanical parts, such as precision bearings, sliding bearings, etc.

Good casting performance

CuSn5-5-5 alloy has excellent casting performance, is easy to melt and cast, can well fill every detail of complex molds, reduce the formation of pores and inclusions, and ensure high quality and consistency of castings. Its excellent fluidity allows more effective control of the cooling rate during the casting process, thereby reducing the generation of thermal cracks and improving the yield rate. According to statistics from the Foundry Industry Association, the qualified rate of CuSn5-5-5 alloy castings is as high as over 95%.

Excellent corrosion resistance

In a humid and corrosive environment, CuSn5-5-5 alloy exhibits extraordinary corrosion resistance. This is mainly due to the synergistic effect of tin and other trace elements in its alloy composition, which forms a dense protective oxide film, effectively preventing further corrosion reactions. This feature makes CuSn5-5-5 alloy widely used in marine engineering, chemical equipment and other fields, such as seawater pump shafts, valve stems and other key components.

3. Application field refinement

Mechanical engineering field

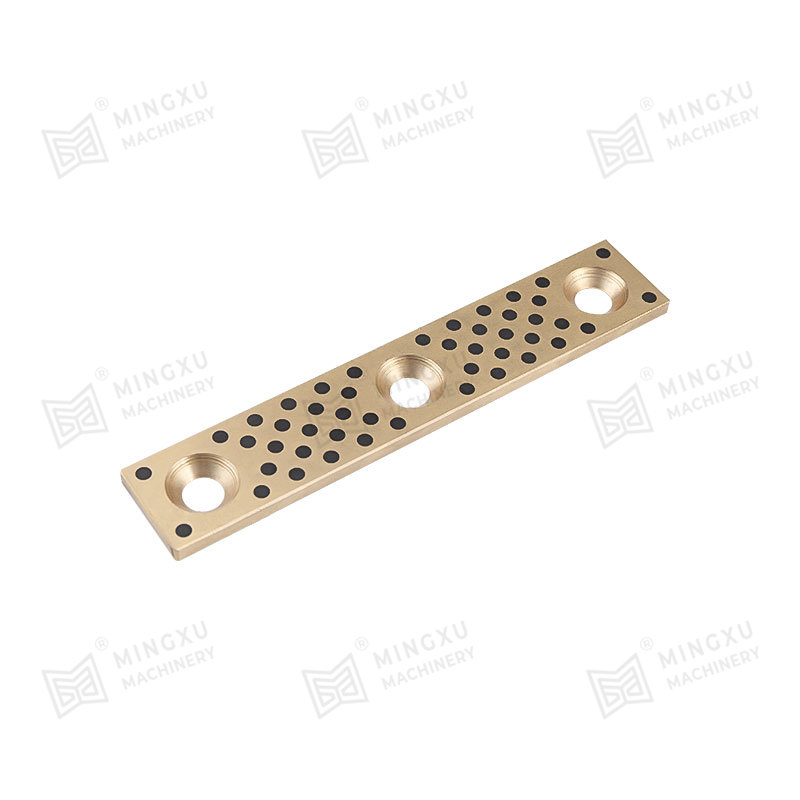

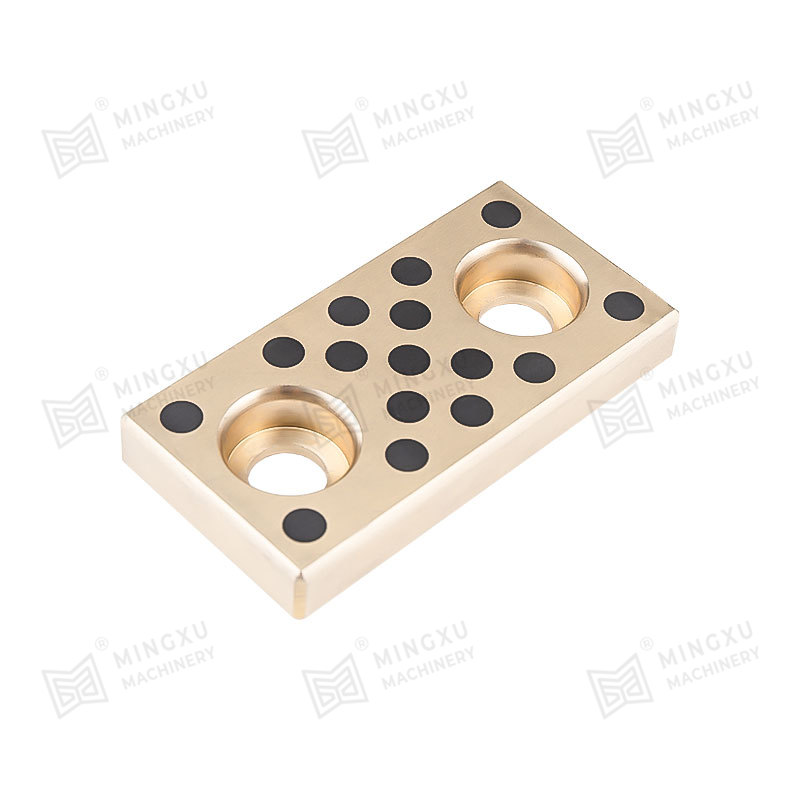

- Precision mechanical parts: CuSn5-5-5 alloy is widely used in the manufacture of precision mechanical parts such as precision bearings, sliding bearings, gears, worm gears, connecting rods, etc. due to its high strength and high wear resistance. These parts can still maintain excellent performance and long life under the conditions of high loads and frequent friction.

- Transmission system: In the transmission system, CuSn5-5-5 alloy is used to manufacture key components such as gears and worms. Its high strength and wear resistance ensure the stability and reliability of the transmission system and improve the overall performance of mechanical equipment.

Shipbuilding and marine engineering

- Marine equipment components: In the field of shipbuilding and marine engineering, CuSn5-5-5 alloy has become the preferred material for manufacturing key components such as seawater pump shafts, valve stems, and propeller bearings due to its good seawater corrosion resistance. These components are exposed to harsh marine environments for a long time, requiring the materials to have extremely high corrosion resistance and wear resistance. The corrosion resistance of CuSn5-5-5 alloy meets the requirements of ISO 9227 standards and can maintain long-term stable operation in marine environments.

Electronic and electrical industries

- Connectors and switch contacts: In the electronics and electrical industries, CuSn5-5-5 alloy is used to manufacture connectors, switch contacts and other components due to its good electrical and thermal conductivity, as well as certain strength and corrosion resistance. These components need to withstand fluctuations in current and voltage while maintaining good mechanical properties and long-term stability. According to industry reports, the application of CuSn5-5-5 alloy in the electronics and electrical industries is growing at a rate of about 5% per year.

4. Processing Technology

The processing of CuSn5-5-5 alloy includes smelting, casting, heat treatment, machining and other links. During the smelting process, the temperature and time must be strictly controlled to ensure the uniform distribution of the alloy components; during casting, the mold temperature and casting speed must be paid attention to in order to obtain high-quality castings; heat treatment adjusts the internal structure of the alloy through the heating and cooling process to improve its mechanical properties and corrosion resistance; machining is carried out according to the requirements of specific parts, such as turning, milling, drilling and other processing to obtain precise size and shape.

5. Future Development Trends

With the advancement of science and technology and the development of industry, the application field of CuSn5-5-5 cast copper alloy will be further expanded. On the one hand, through the improvement of alloying technology, such as adding trace rare earth elements, its strength and wear resistance can be further improved, while maintaining or even improving corrosion resistance; on the other hand, with the help of advanced processing technology and molding technology, such as 3D printing, precision casting, etc., more complex shapes and higher precision parts can be produced to meet more diversified needs. In addition, the enhancement of environmental awareness will also promote the development of recycling and reuse technology of CuSn5-5-5 alloy, reducing energy consumption and environmental pollution in the production process.

6. Conclusion

CuSn5-5-5 cast copper alloy plays an irreplaceable role in multiple industrial fields with its unique performance advantages. With the continuous advancement of technology and the growing demand for applications, the future development prospects of CuSn5-5-5 alloy are broad. For material scientists and engineers, in-depth research and development of new properties, new processes and new applications of CuSn5-5-5 alloy will be an important driving force for the sustainable development of related industries. At the same time, strengthening international cooperation and exchanges and jointly exploring more possibilities of CuSn5-5-5 alloy will also contribute more wisdom and strength to the development of global industry.

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. has been engaged in the research and development and manufacturing of copper alloy products for more than ten years. Its products include JDB solid inlaid self-lubricating bearings, steel-copper sintered bearings, SF-1 self-lubricating bearings, SF-2 boundary self-lubricating bearings, FB090 copper bearings and other products. They are widely used in many mechanical manufacturing fields such as the automotive industry, engineering machinery, metallurgical equipment, mining machinery, injection molding, molds, textiles, printing, etc., and are deeply recognized and loved by domestic and foreign customers.

Contactez-nous